To work on a project in Antarctica—how awesome would that be? A team of engineers was charged with the task of upgrading the heating system in the U.S. Antarctic Program Building #155. They decided that radiant floor heating was the correct solution, but they required a system that would provide reliable warmth, be efficient with energy usage, and could be installed easily without the use of concrete due to the difficulty of pouring concrete in freezing temperatures. Warmboard outshined all other systems and was chosen to keep the researchers and scientists warm and toasty.

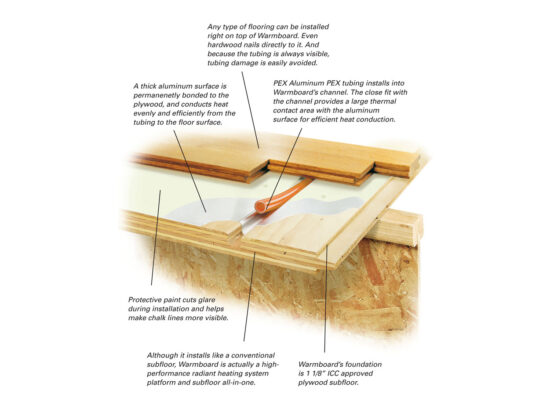

The What: Warmboard, Inc., based in Aptos, California, manufactures its namesake product Warmboard—a radiant floor panel that ingeniously serves also as a structural subfloor. Warmboard consists of two main ingredients. The bottom layer is plywood (4’ x 8’ x 1-1/8” thick) made of 7 ply layers of Douglas Fir which is cross-banded and bonded together with exterior grade phenolic adhesive, as well as grooved in an efficient curvilinear pattern to accommodate the tubing that carries the water. The top layer is made of high-grade, 24-gauge aluminum surface which is bonded to the plywood and inset continuously into the curvilinear grooves.

The Warmboard system can be broken into different zones each controlled by its own thermostat. The water supply can come from a variety of sources including a domestic hot water heater or a solar thermal hot water heater. A complete system can gain between 7 and 11 LEED points.

Warmboard exemplifies a product of sustainable manufacturing. It not only serves two purposes in one product, but also is constructed of environmentally sound materials and addresses long term durability. Manufactured in the United States, the plywood material comes from trees grown in Oregon and complies with the Oregon Forest Practices Act which promotes sustainable forest harvesting, protects wildlife habitats, and limits clear-cutting. The construction of the plywood is resistant to warping, shrinking, or twisting and approved as a structural panel by APA (The Engineered Wood Association).

Containing 20% recycled aluminum, the aluminum plate is durable and waterproof, and is compatible with various floor finishes (hardwood, carpet, tile or stone) which can be placed directly against the aluminum.

The Warmboard system helps reduces waste in the manufacturing process as well as at the jobsite. Warmboard, Inc’s CAD design services customize the Warmboard panels for each project and ship out the exact amount of panels. Consequently, the crew on site can install two building systems in one pass, install the subfloor like any other structural plywood, and minimize cutting and waste.

Radiant Flooring Primer: 2000 years after the Romans developed the concept of radiant floor heating, the Germans, Swiss, and South Koreans are now the biggest users of hydronic heating in their buildings.

A radiant heat system conducts heat from the water in a tube to the surface of a radiant floor. The radiant heat then travels through the air to warm up a space. It is the simple law of physics: as conductivity goes up, water temperature goes down. The high conductivity of Warmboard allows the water temperature to be between 90 degrees and 110 degrees which is less than that required for a typical radiant flooring system. Consequently, lower water temperatures require less energy to heat up the water and helps reduce utility bills.

Radiant heating gives the benefit of neutral if not better indoor air quality than other heating systems. For example, unlike the forced air system which is prevalent throughout the United States, it does not blow dust, allergens or hot air around, nor does it produce any noise.

The Who: Terry Alsberg, architect, boat builder, and entrepreneur, invented Warmboard in 1992 while he was trying to install a radiant flooring system in his home remodel. Unfortunately, the existing 2 x 6 redwood floor framing joists could not support the load of concrete in which typical radiant floor water tubing is embedded. In trying to find an alternative solution, an idea dawned upon him: how about making the radiant panels with a structural quality? He went to his drafting table and within 15 minutes, doodled a few tubing patterns to figure out which pattern would have the most efficient delivery system.

After building a prototype in his garage, Terry, with the help of his father, filed a patent for it: structural plywood with a modular groove pattern which has conductive material within it. Four years and six revisions later, the patent was approved in 1998.

During that patent application period, Terry talked to 17 companies in search of someone who could manufacture Warmboard. It was the last company—Jeld-Wen Windows & Doors that agreed in 1996 to manufacturer his product. With close to 4000 hours of work and little income, Terry’s persistence and patience had finally paid off. In 2002, Jeld-Wen spun off Warmboard and Terry took it over as he re-invented his business to sell the product and grow it to what it is today.

As a proponent for energy-efficiency, Warmboard, Inc. has contributed to the last three Solar Decathlons organized by the U.S. Department of Energy, and donated its Warmboard system to numerous top-placing teams. This year, the company sponsored the Refract House built by Team California which consists of California College of the Arts and Santa Clara University.

Products that are efficient with labor as well as materials are critical to paving the way for efficient and sustainable design and construction. Warmboard has succeeded in that and inspires innovation from the rest of us.

Be the first to comment