With increasing urbanization and development, increasing floods and droughts due to climate change, and diminishing fresh water resources, stormwater management is a real and urgent topic of discussion. Recently I came across a promising permeable pavement solution at the Taiwan International Smart Green City Expo/Taiwan International Green Industry Show — the JW Pavement Eco-Technology. Without sacrificing the strength and durability required of any type of pavement and roadway system, it simultaneously helps solve multiple issues including stormwater management, groundwater replenishment, and waste diversion.

The What:

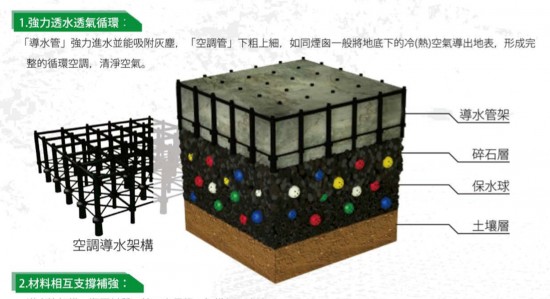

The JW Eco-Technology Pavement (JW Pavement) is classified as a load-bearing structural pervious pavement that can be used in walkways, plazas, parking lots, driveways, and roadways. From the bottom up directly above the soil layer, the JW Pavement system consists of:

- Sub-base layer of recycled plastic hollow drainage balls (optional)

- Sub-base layer of gravel drainage rock

- Pavement layer of Aqueduct Assembly with poured concrete

The Aqueduct Assembly is the key component that enables the permeability of the JW Pavement assembly. It is a three-dimensional structural grid that is the conduit for drainage but also essentially replaces the steel reinforcement in typical concrete construction.

Technical Specifications

Within a structural grid unit, each vertical member contains a hollow cylinder that serves as the drainage channel. The hollow cylinders alternate between being straight and being conical with the smaller diameter at the top. The structural grid of the Aqueduct Assembly is designed to work with standard concrete to form the pavement layer. The top of each drainage channel is protected with a cover that prevents the flow of concrete into it during a concrete pour. The top of the concrete finish needs to be flush with the top of the drainage channels, which will be exposed after the concrete cures.

- Dimensions of a basic structural grid unit: 70 cm x 70 cm with a height of 10 – 20 cm for pedestrian and regular vehicular applications, and a height of 30 cm for roadway applications.

- Spacing: The drainage channels in a basic unit are spaced apart in a 10 cm x 10 cm grid formation.

- Porosity achieved with the flow of water through the drainage channels for full infiltration to underlying subsoil: 12 cubic meters/hour/square meter, or 200 liters/minute/square meter.

- In comparison, porosity for pervious concrete ranges from 80 – 700 liters/minute/square meter.

- Strength: Once an appropriate concrete mix is poured and cured within the Aqueduct Assembly, the strength of the assembly can reach 7,254 – 28,162 psi (pounds/square inch), or 510 – 1980 kgf-cm squared (kilogram-force/square centimeter), or 3.6 – 14 tons/square inch, strong enough for regular vehicular traffic. For roadways with high volume traffic such as freeways however, the JW Pavement assembly will need to be supplemented with steel reinforcement.

- In comparison, strength for pervious concrete: 400 – 4000 psi.

- Finish texture and pattern of the concrete surface: Based on a wide range of options created from different aggregate sizes and different patterns designed around the 10 cm x 10 cm grid.

- Warranty: ten years based on the first large-scale project installed ten years ago. Product predicted to last well beyond thirty years.

General State of Conditions

Stormwater runoff typically flows into storm drains and pipes that connect to rivers, streams, lakes, and oceans. The majority of today’s existing infrastructure is not designed to reduce stormwater runoff. Meanwhile, groundwater supplies have been diminishing over time and faster than they have been recharging as humans extract potable water from aquifers and springs. Why let stormwater run off when it can be redirected to replenish the groundwater supplies?

Benefits and Advantages

The JW Pavement Eco-Technology addresses the issues listed above as well as the diversion of plastic waste. Its built-in system of drainage channels in the Aqueduct Assembly can help:

- Reduce stormwater runoff by providing numerous inconspicuous outlets that provide direct access for stormwater to flow into the ground.

- Slow down runoff and minimize the potential for flooding.

- Increase the water infiltration rate into the soil, thereby replenishing and recharging groundwater sources.

- Divert plastic bottle waste by recycling them for the production of the Aqueduct Assembly and hollow drainage balls.

- Reduce pavement surface temperature and thereby cooling the surrounding air and reducing the heat island effects by storing and evaporating water. (The JW Planting Pavements accomplishes this especially well.)

- Reduce air pollution by capturing CO2 and other polluting particulates in its drainage conduits.

The Who:

The inventor of JW Pavement Eco-Technology, Mr. Jui-Wen (JW) Chen 陳瑞文, has been working since his teenage years, starting off as a subcontractor on a construction site and owning various businesses over the years. He currently runs his two businesses, Ping Tai Co., Ltd., which handles design and manufacturing, and Chyi Shyang Construction Company which handles sales and installation of the JW Pavement Eco-Technology as well as the training of other contractors in its technology. Mr. Chen also founded the non-profit organization Taiwan Association of Sustainable Ecological Engineering Development whose mission is to educate, research, promote sustainable and ecological engineering technologies locally in Taiwan as well as internationally.

Mr. Chen’s curiosity since childhood and conviction to help save the environment has resulted in his creation of ten patented inventions throughout the years. Back in 2003, Mr. Chen won the Gold Medal from the International Exhibition of Inventions of Geneva (Salon International des Inventions de Genève) and since then, has won numerous innovation awards and patented his invention in over ten countries including the US, China, and Australia. As a champion of sustainable engineering, Mr. Chen has gained the respect of many academics who have worked with him to develop and substantiate his inventions.

Recently I had the opportunity to meet Mr. Chen in Taipei. He is quiet spoken and unassuming, yet he is so passionate when it comes to talking about saving the environment and his fervent belief that the JW Pavement assembly is a win-win solution for pedestrian pavements and vehicular roadways. In the last ten years, Taiwan and China have been the testing grounds for validating the durability and effectiveness of Mr. Chen’s technology. With solid proof in hand now, he has the grand vision of globally pushing out the JW Pavement Eco-Technology because stormwater management and groundwater replenishment are universal problems encountered in every country.

What Are We Waiting For?

Interlocking pavers, grass pavers, and porous concrete are all great stormwater management solutions most often found in driveways, parking lots, and pedestrian walkways. People are still hesitant about installing porous concrete at a large scale with constant vehicular traffic due to concerns with strength capacity and long term maintenance. The JW Pavement’s inclusion of concrete in its design tackles the problem of strength capacity and long-term durability and presents an advantage over other pervious pavement systems. It addresses multiple environmental issues and has strong potential to successfully scale jump from individual to infrastructural projects.

Be the first to comment