Can the construction industry help divert plastics from the world-wide waste stream? Could a green replacement for plywood be one of the ways to help solve the problem? During my attendance at Ecobuild 2010 in London earlier this year, I came upon a smartly designed exhibitor booth. I was drawn to its interactive displays, see-through boxes holding various used plastics items which many of us call our bane of existence, and graphic text large enough to catch my attention from a distance, “What is EcoSheet”? Of course, I had to go up close to read the fine print.

The What: EcoSheet is a green alternative to plywood and made from 100% recycled plastics consisting of recycled polymers and other items such as electrical/electronic equipment waste. The beauty of the engineered panels is that they are impervious to rain and humidity and thus can withstand being stored outdoors. EcoSheet is as strong as, but lighter than plywood, can be cut with standard tools, and has two smooth “A” faces. Its standard plywood dimensions (4 ft x 8 ft and 2440 mm x 1220 mm) and other attributes make it an easy substitute for plywood.

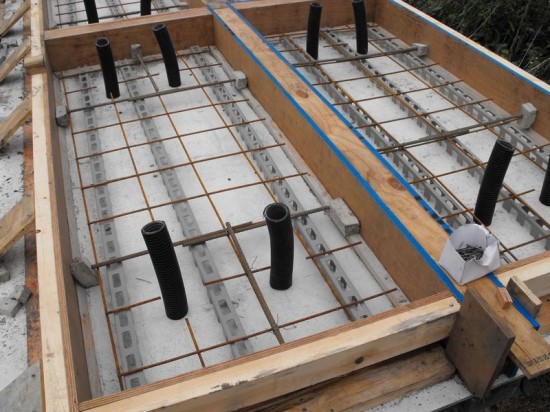

EcoSheet is designed to be used for formwork, hoarding panels, and signage/displays, re-used multiple times, and recycled at the end of its life-cycle. 2K Manufacturing, based in Luton, United Kingdom, uses a patented process that binds different plastic polymers called powder impression molding (PIM) to create EcoSheet.

The Who: Childhood friends Omer Kutluoglu and Turul Taskent have spent the last 2 plus years planning and developing EcoSheet. CEO Mr. Kutluoglu, a bond trader turned serial entrepreneur, put the business plan together while Operations Director Mr. Taskent, an engineer specializing in composite plastics, designed PIM-compatible molds for Ecosheet.

Rewind back to a few years ago. Mr. Kutluoglu and Mr. Tural visited a PIM factory in South Wales and determined that they could use the technology to create a useful product. They wanted to create a replacement for a product that uses a lot of virgin material such as plywood and thus started the development of EcoSheet. Since then, they have worked with contractors to test run their product in actual construction projects and obtain feedback from the workers. Additionally, Ecosheet has garnered much attention from the building industry, winning the 2007 Innovation Award from the Chartered Institute of Building and becoming a finalist for U.K.’s National Recycling Awards’ Best Recycled Product category in 2009. 2K Manufacturing will start full production of EcoSheet in June/July of this year to focus on U.K. market and has plans to sell to the U.S. market in the future.

Ecosheet excited me the most at Ecobuild 2010’s products exhibition. I see a lot of opportunities in replacing plywood while saving wood for other higher level usages. Especially in this state of economy, it’s gratifying to see innovative entrepreneurs push the creative envelope, receive industry and financial support, and succeed in taking a concept through manufacturing. Peter Ball, Head of Sales at 2K Manufacturing, states:

“We plan to make a panel that wins hearts, minds and wallets by being environmentally, operationally, and commercially a better option than plywood.”

Think of the tremendous potential of how much plastic we can divert from the waste stream if we could use EcoSheet for building formwork, subfloors, exterior sheathing, shear walls, signage, temporary fencing and so forth.

Be the first to comment