The Xinyi Central Business District in Taipei, Taiwan is home to a handful of buildings designed by well known architecture firms including C.Y. Lee & Partners of Taipei 101 fame, Paris-based Vincent Callebaut Architectures, U.S.-based Richard Meier and Partners, and Taipei-based KRIS YAO | ARTECH. Recently I had a chance to tour the office headquarters of Hua Nan Commercial Bank, a Taiwan EEWH-Gold and USGBC LEED-Gold certified building designed by fellow Cal alum Kris Yao and his firm KRIS YAO | ARTECH (姚仁喜 大元建築工場).

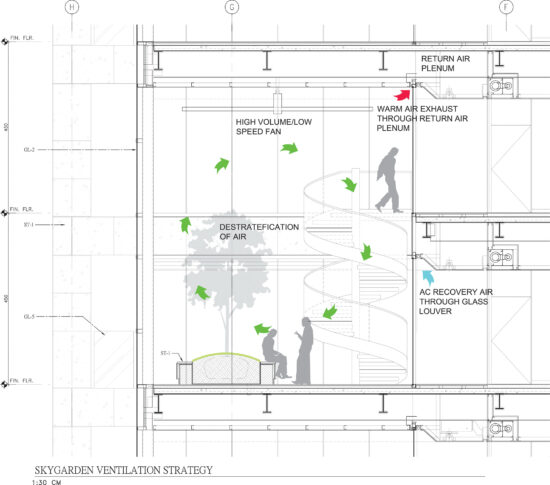

The Hua Nan Commercial Bank Headquarters is located in a transit friendly neighborhood with easy access to numerous bus, subway, and train lines. It is generously set back from the street front, surrounded by a landscaped plaza, and anchored by a three-story podium topped with a twenty-four story tower above it. The building’s most striking feature is its rhythmic lattice of an exoskeleton system that acts as a shading system, which is highly appropriate for the extreme sun and hot weather conditions that occur for two-thirds of the year in Taiwan. The structural exoskeleton also allows for a continuous glass curtain wall around the building and the interior spaces to be column-free. Interior-wise, the ground floor lobby is grand yet minimal, outfitted with carefully selected stone finishes and meticulously designed metal panels that befittingly reference ancient Chinese coins. Each floor above the third floor is organized around a west-facing double height “sky garden” that serves as a buffer zone to help reduce heat gain and provides a pleasant space for respite and informal meetings.

Sustainable Site Features

- The bicycle storage located in the basement provides 60 parking spaces and is supported by twelve changing and showering facilities equally split between male and female.

- All landscaped areas including the third floor roof garden are vegetated with native, drought-resistant plants.

- Water for landscape irrigation is provided by the grey water treatment system and rain water harvesting system.

Energy Efficiency Features

- The façade design blocks direct sunlight while allowing indirect daylight into the building interiors. Combined with daylighting strategies such as daylight/photo sensors to control lighting along the windows and an optimized floor plan depth of 8 meters (26.24 feet) where natural daylight is mostly sufficient on a sunny day, the building envelope design helps contribute to the interior lighting energy saving efforts.

- The façade design is designed for optimal solar transmittance into the building interior during the summer and optimal capture of solar heat gain in the building during winter.

- Each floor has an electric meter and the building owner closely monitors electricity usage.

- Heating and cooling design: the building is serviced by two types of HVAC systems. Levels B2F to 3F, which are mainly public spaces (parking, reception, lobbies, exhibition hall, conference centers, kitchen, cafeteria, etc.), have cooling only. The spaces are served by either the central chilled water air conditioning plant system supplemented with air handling units (AHU) or fan coil units (FCU). Levels 4F to 27F, which contain commercial office spaces, have cooling and heating and are served by variable refrigerant flow (VRF) multi-split direct expansion (DX) systems, which comprise of one outdoor condensing unit and multiple indoor units on each floor. Outdoor air ventilation is carried out by heat recovery ventilators (HRV).

Indoor Environmental Quality Features

- Built-in floor mats are installed at all entry ways of the building.

- All filtration media for the HVAC systems are MERV 13 and above.

- CO2 sensors are located in all occupant zones that have an occupant density of more than 25 people per 1000 square feet.

- Lighting controllability is available to 90% of the occupants. Strategies include individual task lighting and multi-occupant area lighting control zoning.

- Measurements to be taken on a 10-foot grid to verify the daylight performance in all spaces.

- A post-occupant survey on thermal comfort will be conducted within 18 months after full building occupancy. The goal is to have less than 20% of occupant dissatisfaction. If there is more than 20% dissatisfaction, the the building management will take corrective measures to ensure that occupant needs are met.

- Low-emitting VOC finishes such as adhesives, sealants, paints, coatings, and flooring systems were used throughout the building interior. (Note: One of the main challenges in using low-VOC adhesives and sealants is that typical projects in Taiwan have compressed construction schedules that consequently require adhesives to dry fast and hold tight. However, many of the low-VOC products cannot compete with their conventional counterparts in terms of pricing, availability and drying time, and thus often resisted by the local contractors. The project team had to closely work with the contractors to ensure that every low-VOC product was LEED compliant and schedule-effective as well as educate the vendors and workers on the use of the products.

As a person with mostly construction project experience in the San Francisco Bay Area where construction waste recycling is common practice and required, I was curious to find out how it is handled in Taiwan. As with many projects in the U.S., a central waste management area was set up on the Hua Nan Commercial Bank construction site with separate and clearly labeled designated areas for categorized materials: wood, metal, plastics, paper/cardboard, concrete, and comingled general waste. More detailed and smaller waste storage areas were set up as needed closer to where construction activities took place. A designated waste hauler was responsible for hauling out all wastes from the central waste management area and taking them to the respective recycling facilities per each material category. I was happy to learn that the Hua Nan Commercial Bank headquarters project recycled and diverted 76.68% of its construction waste.

In preparation of writing this article, I would like to thank Kathy Chiao of KRIS YAO | ARTECH; KRIS YAO | ARTECH’s onsite construction supervisor Calvin Chen who has relentlessly worked onsite from construction start to a year after close-out and shared with me many of his construction battle stories which makes me have a very high regard for construction supervisors representing architecture firms; and Lizzie Gerock of SL+A International Asia, Inc., the certifying LEED consultant on the project.

Hi Mignon, I am doing research here tonight trying to find Director of Design who I could reach out to with an opportunity to come on board with one of my client companies who does high end, high density, multi family projects in CA. WHERE do I turn? 😉